No. 1 trusted partner for nanoporous layers development and production

Thin-film nanoporous layers (NPL) are essential in sensing and electrochemical products. Products that are critical for creating a healthier and more sustainable future. Companies with commercial products in these markets are struggling to develop improved NPL to boost the performance of their product.

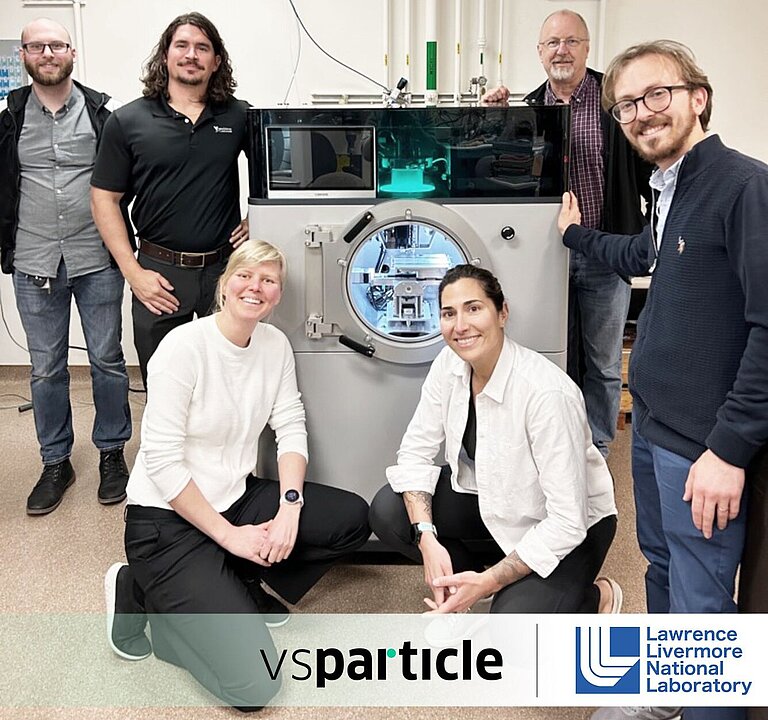

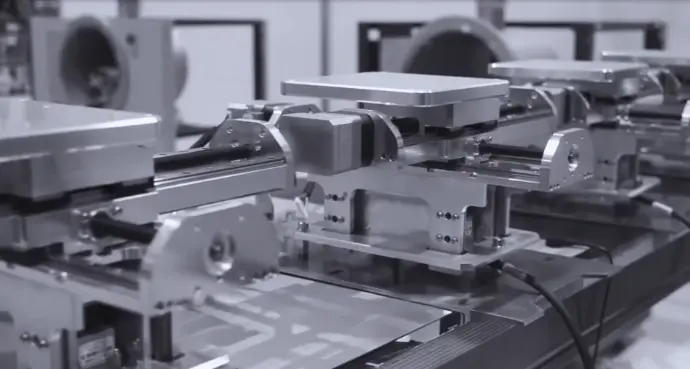

Over the past decade, VSParticle has developed a brand new synthesis technology that is fully optimized for fast development and simple manufacturing of nanoporous layers. By providing NPLs as a service, VSParticle is the No. 1 trusted partner for reliable NPL development and production.

Trusted by companies

We collaborate with world-leading institutes to support their mission

We help our customers developing better nanoporous layers for

Energy applications

Energy applications

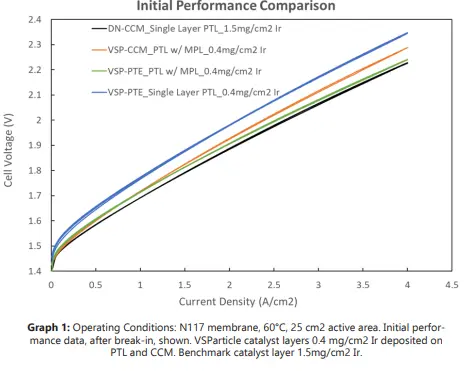

- PEM-WE

- Fuel cells

- CO2 Conversion

- N2 Conversion

Sensing applications

- MOx gas sensing

- Electrochemical sensing

- SERS

Our core technology sets new benchmarks for NPLs

![]()

Material diversity

Compatible with 40+ materials,

Possible to incorporate alloys, mixed-metal compositions

![]()

Scalability

No polymer binders and chemicals thanks to patented dry deposition technique

![]()

Homogeneous layers

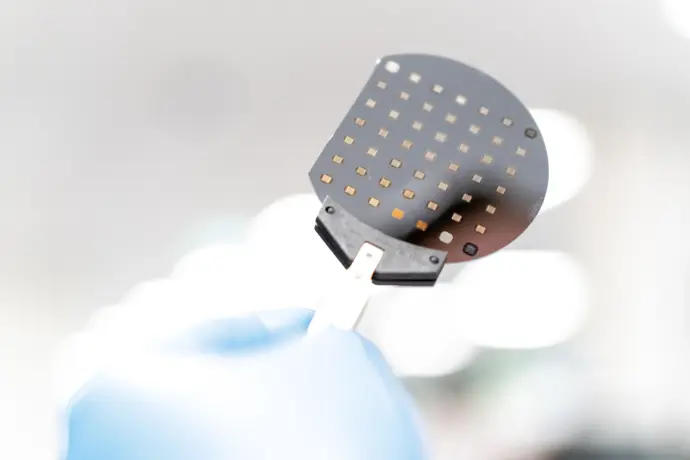

Uniform nanostructures with controlled loading

![]()

High porosity and surface area

60-80% porous structures, outperforming typical porosity benchmark

![]()

Substrate agnostic

Deposition on PTLs, Si wafers, ITOs, or clients' substrate of choice

Why choose VSParticle's on-demand deposition service?

Zero CAPEX validation for fast-tracking tech validations

If your product depends on high-performance nanoporous layers, whether in electrolysis, sensing, catalysis, or thin-film devices, every iteration counts. By outsourcing your complex nanoporous layer fabrication to us, you can validate performance, adjust material choices, and improve layer properties, all with zero CAPEX and minimal lead time. This means faster R&D cycles, more confident material design decisions, and a shorter path to market success.

Scaling up to production volume

Bringing a new product to market is a race specially for companies working with advanced nanomaterials. Whether you're refining an early prototype, refining your product or preparing for large scale production, we support your scale-up. This allows you to meet technical milestones faster, respond to market demand with confidence, and stay competitive, whether you're defending your niche or entering a new one.