Modern catalysts for today’s global challenges

Solid catalysts are at the heart of 90 % today’s energy and chemical industries. Catalysts have a vital role in both established and emerging industrial processes, and remain indispensable as we develop new processes while addressing societies greatest challenges linked to sustainable energy production and climate change.

Developing new and more efficient electrocatalysts is an essential step to securing a sustainable future powered by clean and renewable energy.

The need to accelerate electrocatalyst development

Classical heterogeneous catalysts (in which a solid catalyst is used for gas/liquid phase thermochemical reactions) have seen over 150 years of improved understanding and incremental enhancements which has resulted in their widespread adoption within industry and academia.

However, the need to develop clean, efficient, and sustainable energy sources with effective storage solutions has led to a surge of interest in electrocatalysts, specifically for water electrolysis and fuel cell applications.A major driving force for this electrocatalysis boom is the wide-ranging applications in which electrocatalysts are employed, and the need to screen a vast array of potential material compositions to obtain novel electrocatalysts that are highly active, stable, cheap and industrially scalable.

At present, noble metal-based materials (Pt, Ir, Ru, Rh) are the most active for both HER and OER. In order to make these electrochemical processes scalable and commercially viable, their noble metal contents must be lowered or replaced by cheaper alternatives such as Ni, Fe, Co and Mn (amongst others).Methods to rapidly and reproducibly synthesize a wide variety of mono/bi/multi-metallic electrocatalysts are therefore not only highly desirable, but crucial for today’s researchers to prepare and compare novel electrocatalysts to meet the modern day energy and chemical challenges.

VSPARTICLE & electrocatalysis

Lab-scale electrocatalyst synthesis made easy

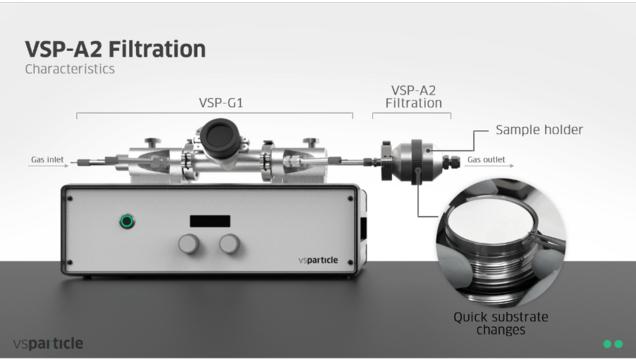

VSPARTICLE’s spark ablation technology offers a versatile method to rapidly produce a wide range of model electrocatalysts. Using the VSP-G1 nanoparticle generator in combination with the VSP-A2 filtration deposition accessory, monometallic and alloy nanoparticles are produced that can be directed onto common porous substrates such as carbon cloth or metallic felts/meshes . This unique sample preparation method enables researchers to make new materials that can be tested or characterized within 1 hour.

The compact size of the VSP-G1 nanoparticle generator ensures that VSPARTICLE’s technology is easily accommodated in every research laboratory.

Fast-track electrocatalyst screening

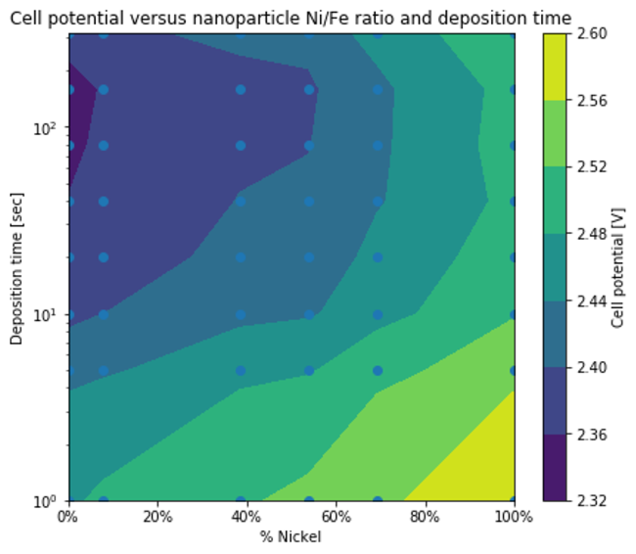

The ability to quickly screen multi-element electrocatalysts is accelerated even further using two VSP-G1 nanoparticle generators connected to the VSP-P1 NanoPrinter. To illustrate the possibilities with such a setup VSPARTICLE, in collaboration with Avantium, screened 64 different Ni-Fe electrocatalysts in OER in high-throughput. VSPARTICLE’s technology enabled researchers to screen the performance of 64 different electrocatalyst composition. By empowering today’s researchers with the most advanced products in our portfolio we are able to significantly accelerate the development of novel electrocatalysts.

Read More

In the last decade, the development of Electron Microscopy (EM) analysis tools has advanced significantly, with the addition of in-situ characterization capabilities. Especially for catalysis, material science and electronics research, this offers new insights into “black box” processes on the nanoscale. The EM analysis enables researchers to study material behaviour in real-time, under real-world conditions. Institutes all over the world are experimenting with the newest in-situ systems for Transmission Electron Microscopy (TEM), Scanning Electron Microscopy (SEM), Energy-Dispersive X-ray Spectroscopy (EDXS) and Electron Energy Loss Spectroscopy (EELS).

VSPARTICLE is on a mission to speed up research in new nanomaterials by automating the production of advanced nanomaterials. The company introduced the VSP-G1 with the philosophy that making nanomaterials for research should be quick and easy. With the option for a four-month trial period the technology will be accessible for any researcher.