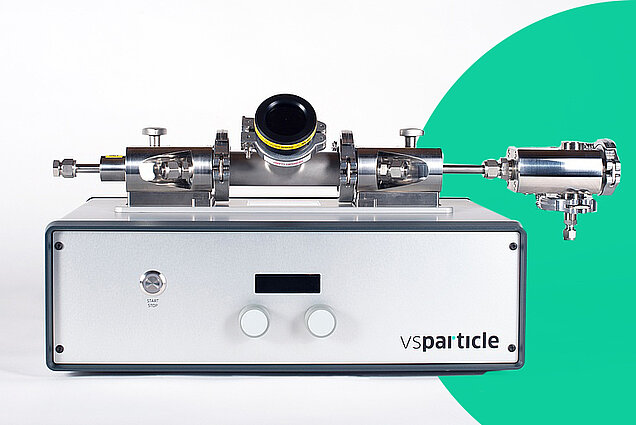

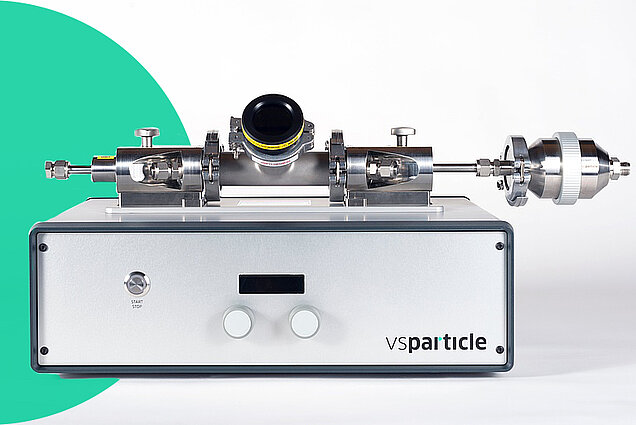

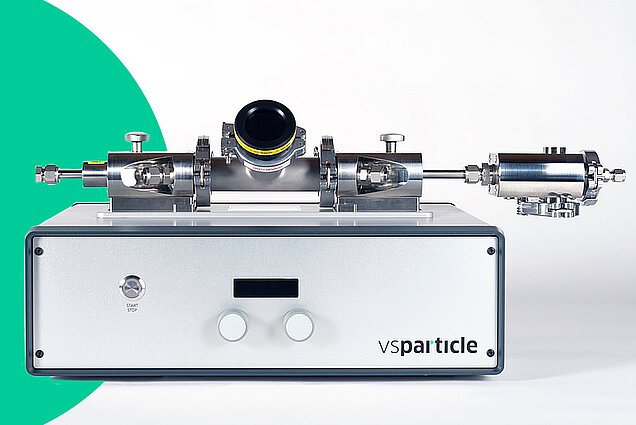

VSP- A Series

The VSP-A Series accessories can be easily connected to the output of the VSP-G1, enabling any researcher to produce nanoparticle samples in a matter of hours, with minimal effort.

Easy & quick sample preparation

Typical sample preparation time is 1-60 minutes. Go from hypothesis to result in the same day. With VSPARTICLE Accessories pure nanoparticles are generated and deposited on any kind of substrate.

Dispersed particles (A1), Coated filters (A2), Porous layers (A3)

With VSPARTICLE Accessories pure nanoparticles are generated and deposited on any kind of substrate. You can make a sample with dispersed particles, a nanoporous layer or coated filters with great material flexibility. You can use any kind of (semi)conductive source material: pure, alloys, compacted alloys, mixed materials, oxides and other combinations.

TECHNOLOGY

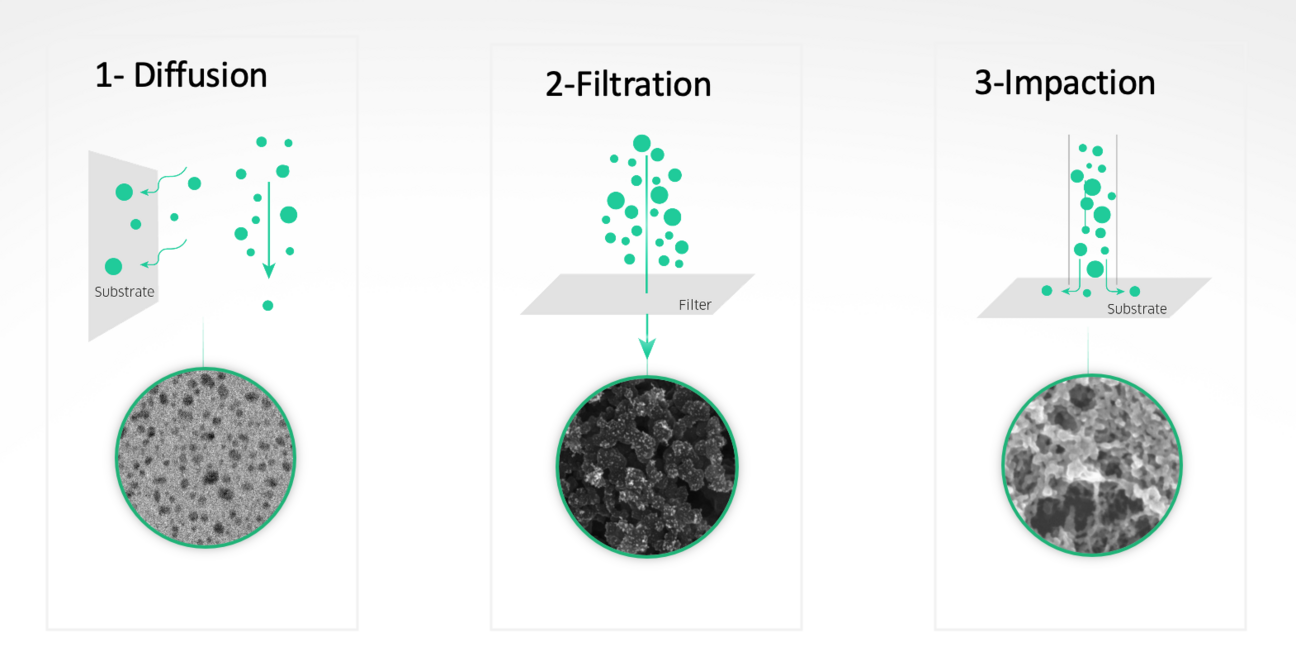

The spark ablation process used inside the devices is a purely physical process that only requires electricity, a carrier gas and electrode material to produce clean nanoparticles. No additional chemicals are required for the production or to stabilize the particles in the aerosol. The produced nanoparticles can be directly incorporated into the next process step or applied in a product by, for example, impaction, electrostatic precipitation or filtering. This way the unique physical properties of the nanoparticles are directly available in the product. The carrier gas can simply be recirculated, minimizing the environmental impact of the process.

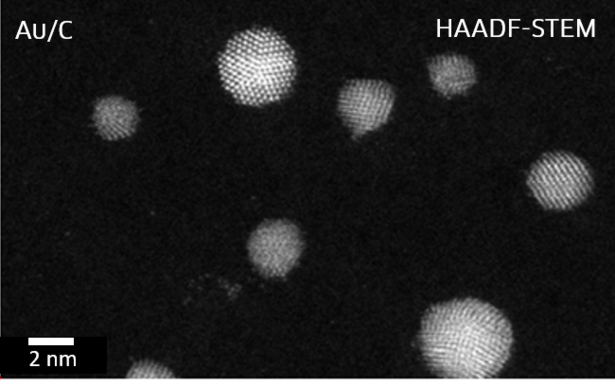

VSP-A1 Diffusion Accessory

For well-dispersed nanoparticles on 2D substrates

- Dispersed, unagglomerated particles

- Sample ready in 1-10 minutes

- From hypothesis to particle sample in less than one hour

- Sample size 10x10 mm

- Substrate types: e.g. (in-situ) TEM chips, Electrodes, (doped) Si chips

- Production rate: 1-10 mg per hour

VSP-A2 Filtration Accessory

High coverage on porous substrates

- Mix & match oxides and metallic nanoparticles

- Collect particles with in-line filter

- Bottom-up catalyst fabrication

- Type of substrates: porous membranes, electrospun wires, carbon cloth

- substrate size ø47 mm

VSP-A3 Impaction Accessory

Deposition of multiple layers of nanoparticles

- Grow a nanoporous oxide layer

- Useful as catalyst support/sensitive material

- Type of substrates: glass, Si, TEM grids, MEMS chips etc

- Max. deposited area: ø3 mm

How to order?

If you wish to set it up in your own lab, you can opt for buying the nanoparticle generator. It is also possible to work in our lab or let vsparticle provide you with some test samples. Just contact our sales team or complete the contact form to see which option fits your situation and research best.

Related Blogposts

As a society, we are still relying heavily on conventional fuels. One of the side-effects of using these fuels is the production of the greenhouse gas carbon dioxide or CO2. A solution to this problem could be.. read more

NEW MATERIALS COULD BE THE CATALYST TO AN ECO-FRIENDLY FUEL CELL

A collaborative effort between University of Delaware research groups leveraged tungsten-carbide nanoparticles to create a more durable, less expensive fuel cell.. read more

Sample preparation for in-situ (T)EM characterisation and measurements is still difficult and often time consuming, but now there are some technological advancements which could drastically speed up this process.. read more