Nanoporous layers for gas sensors

VSParticle offers an innovative single-step solution for depositing nanoporous based on Metal Oxide (MOx) sensing materials onto wafer-scale Microelectromechanical Systems (MEMS) substrates.

This cutting-edge approach supports the development of next-generation chemiresistive gas sensors with enhanced sensitivity, selectivity and scalability for a wide range of applications.

The challenge to enhance gas sensor performance

Chemiresistive sensors based on MOx have become a popular choice for high-performance gas sensing due to their excellent sensitivity, ease of miniaturization, and compatibility with MEMS-based micro-hotplate chips.

However, existing MOx-based technology still faces several challenges, including limitations in sensitivity, power consumption, lifetime, and stability. Furthermore, selectivity and cross-sensitivity continue to be significant issues, as current sensors struggle to accurately identify individual target gases in complex mixtures.

Addressing these limitations is crucial for advancing gas sensor technology and enabling more accurate, reliable, and scalable real-time monitoring solutions —especially in critical applications like environmental monitoring, industrial safety, healthcare, agriculture, defence and consumer electronics.

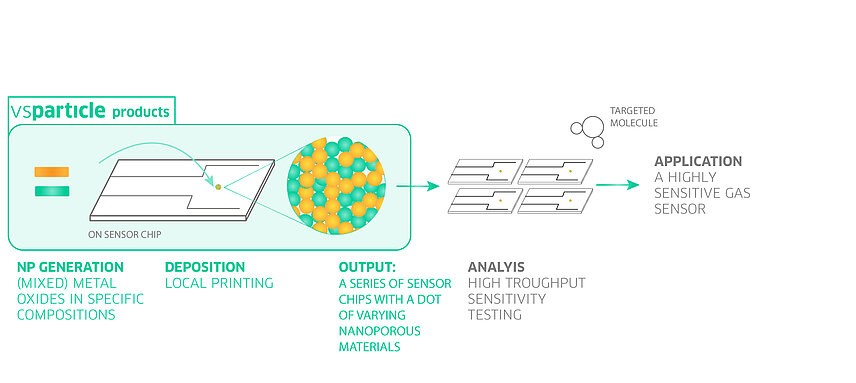

Accelerated screening of gas sensor materials with the VSP-P1 Nanoprinter

VSParticle’s advanced deposition technology is designed to address these challenges and accelerate gas sensor development. Using our state-of-the-art VSP-P1 Nanoprinter, we enable rapid iterations to optimize sensor performance by nano-engineering the sensing layer for maximum surface-to-volume ratios and adjusting the material compositions.

This powerful technology enables the printing of nanoporous metal oxides, binary and ternary alloys, and hybrid materials, including dopants, directly onto substrates. By customizing key process parameters, such as deposition rate, material composition and particle size distribution, developers can create high-performance gas sensors in a fraction of the time it takes with traditional methods.

This flexibility allows for:

- Control over nanoparticle size and layer thickness.

- Fully automated synthesis and deposition of metal oxide layers.

- Rapid screening of various sensing materials to expedite material optimization and accelerate product development.

End-to-end scalability in sensor materials innovation

VSParticle provides a versatile and innovative technology that seamlessly supports all stages of the materials innovation cycle—starting from experimental trials in the lab, to process optimization, and finally, to a middle volume-scale sensor production.

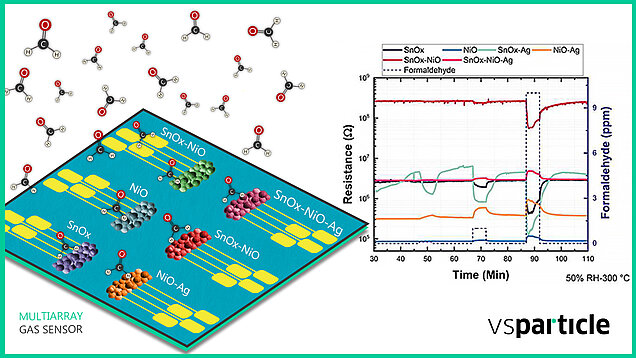

Multiarray gas sensors for formaldehyde detection

One of our projects is focused on developing multiarray gas sensors using nanoporous layers.

In collaboration with leading research institutions, Materials Center Leoben Forschung GmbH and University of Leoben, multiarray gas sensors were fabricated using VSParticle’s technology to improve formaldehyde detection.

By depositing nanoporous layers composed of metal oxides, binary, and ternary alloys, researchers significantly enhanced the sensors’ sensitivity and selectivity.

The multiarray configuration enabled a direct comparison of how different material compositions influence sensor performance, leading to the identification of the optimal composition for formaldehyde detection.

These advancements lay the foundation for next-generation chemiresistive sensors, revolutionizing gas detection through nanomaterial innovation.