SERS Chips - A revolutionary approach for chemical and biological sensing applications

Surface-Enhanced Raman Spectroscopy (SERS) is a highly-sensitive detection technique which can contribute greatly to the development of chemical and biological sensing applications in many different fields. Those fields include among others, food analysis, medical diagnosis, forensics, environmental monitoring and even fine art preservation. Due to Localized Surface Plasmon Resonance (LSPR), SERS substrates provide orders of magnitude electromagnetic enhancement in Raman signal, overcoming the traditional problem of Raman Spectroscopy – its inherent weakness. This is achieved by using nanostructured surfaces, typically with metals such as gold, silver or copper. SERS maintains all the characteristics of Raman Spectroscopy, namely the non-destructive detection based on molecular fingerprint and label-free nature.

Bottlenecks in SERS fundamental research and commercialisation

The key element to achieve the enhancement of the scattered laser signal is the substrate on which the probe is placed. Size, shape and distribution of particles of the nanostructure surface can significantly affect the SERS substrate’s enhancement effect. Therefore, the extraordinary surface sensitivity of SERS substrates requires high precision and is closely related to the advancements in nanomaterials engineering and nanostructure fabrication. Despite the technology’s wide applicability to different fields, there are still many challenges that need to be addressed. For example, most of the methods that are currently being used for SERS fabrication are multistep-processes that require high temperature and/or vacuum conditions, expensive and complex equipment or the use of hazardous precursors. On the other hand, many simpler methods do not allow the deposition of active-SERS patterns at specific locations with sufficient precision.

Those challenges, in combination with the lack of understanding of the exact SERS mechanism, lead to bottlenecks both at the commercialization of SERS substrates as a standard analytical tool, as well as at the fundamental research for their optimization.

The importance of nanoparticles for sensing applications

The key element to achieve the enhancement of the scattered laser signal is the substrate on which the probe is placed. Size, shape and distribution of particles of the nanostructure surface can significantly affect the SERS substrate’s enhancement effect. Therefore, the extraordinary surface sensitivity of SERS substrates is closely related to the advancements in nanomaterials engineering and nanostructure fabrication.

The role of VSPARTICLE technology

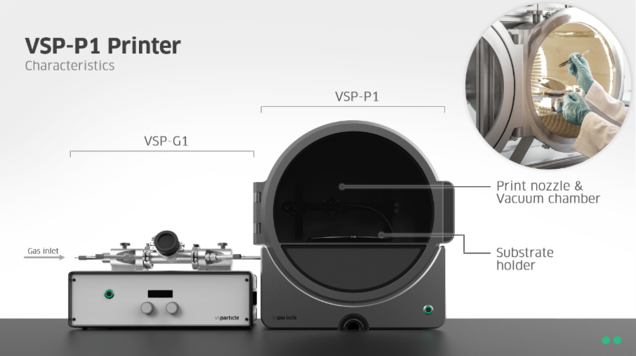

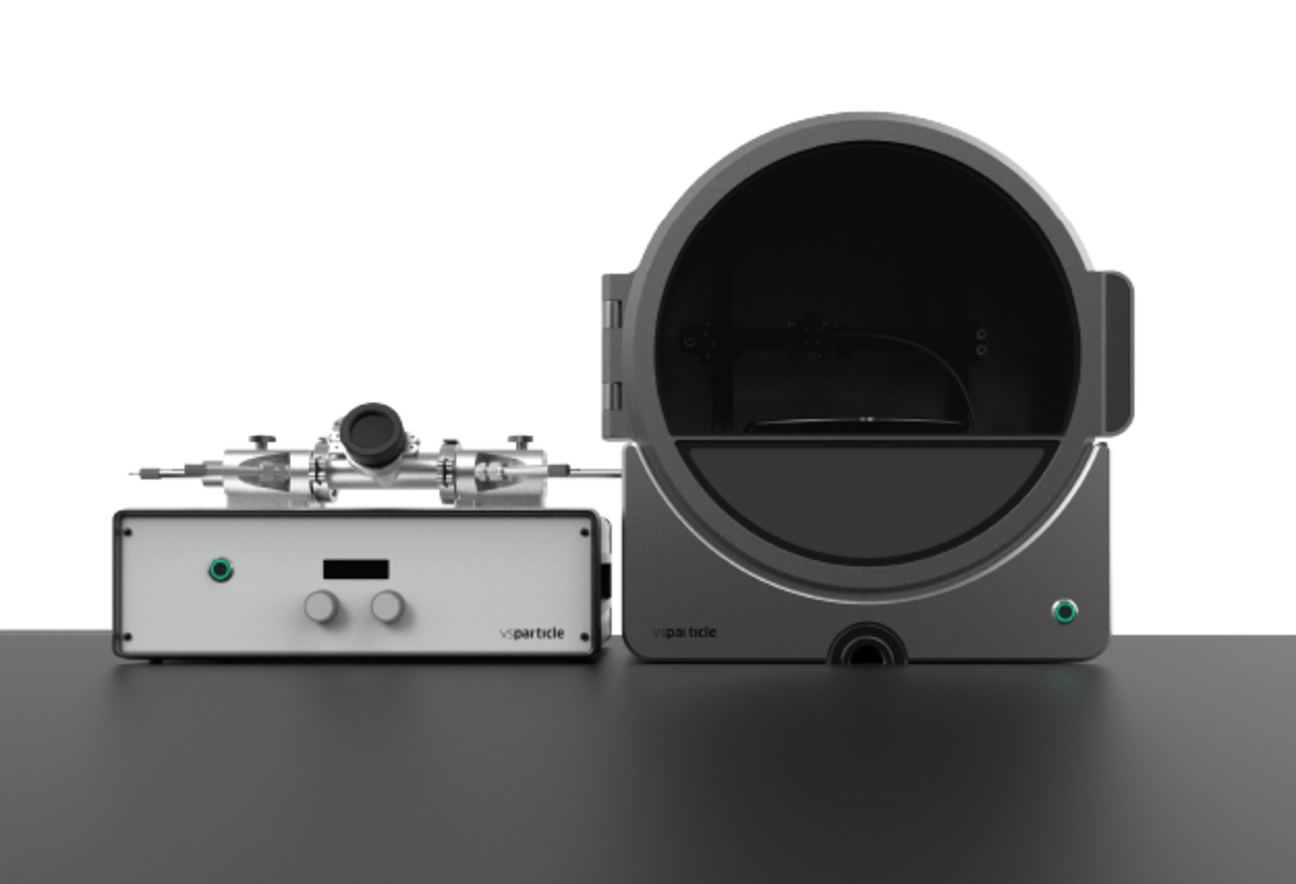

VSPARTICLE has developed a nanoparticle print technology to produce nanostructured noble metal layers by depositing nanoparticles produced by spark-discharge. The process works at ambient temperature and rough vacuum (0.2 mbar) without the use of any chemical precursors. The thickness of the deposited layer can range from sparse distribution of agglomerates to multiple microns.

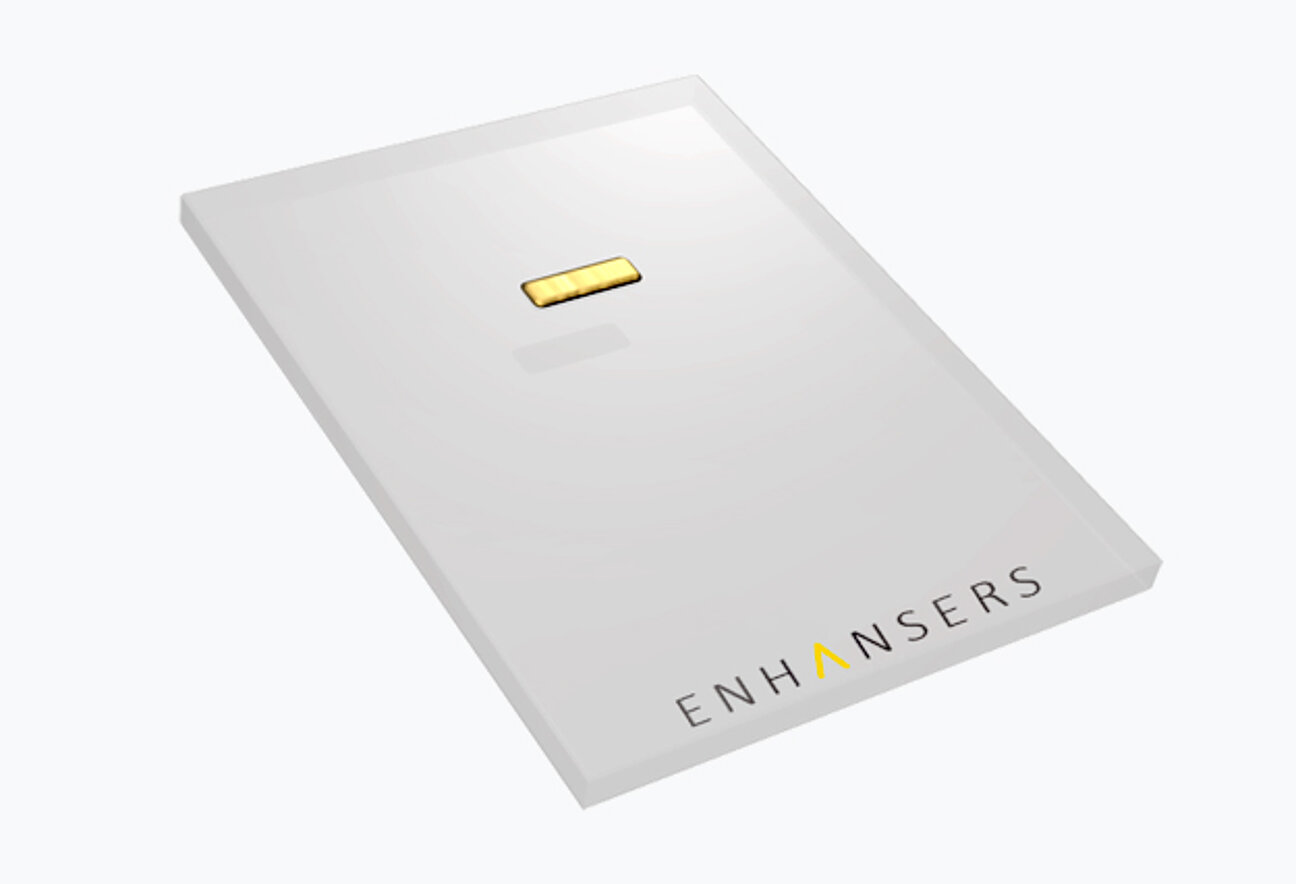

The sensing capabilities of the printed nanoparticles and the nano-porous morphology of the printed layers have proven to be very effective for developing SERS substrates that can be used as a standard tool for chemical analysis. This led to the development of Enhansers, a nanotechnology company solely focussed on the production and distribution of nanostructured SERS substrates on a commercial scale.

At the same time, the versatile technology that is used for the production of nanoparticles is integrated in the fabrication process. Therefore the customer can quickly print new substrates with different material combinations and morphology, without the need to directly handle nanoparticles. This flexibility allows the fabrication of SERS substrates with different structures and material combinations, thus enabling researchers to use this technology for their fundamental SERS research.

SERS substrates fabricated using VSPARTICLE’s technology

A great example of how VSPARTICLE’s spark ablation technology can be applied to overcome the SERS fabrication challenges is its recent application for the development of Cu SERS sensors. This work by Aghajani et.al illustrated that the proposed process can be used in combination with low-temperature thermal treatment in order to tune the morphology of the deposited nanopatterns, resulting in substrates that significantly enhance the Raman signal of Rhodamine B.

Interested in enhancing your Raman measurements?

Check ENHANSERS, our commercially available substrates with unmatched reproducibility and sensitivity

Interested in fundamental SERS research?

Check our versatile nanoparticle printing technology and learn more about how you can quickly print new substrates with different material combinations