Client:

Dr. Cedric D. Koolen

Principal Investigator

Laboratory of Materials for Renewable Energy, EPFL

Research field:

Nanoparticle synthesis for energy applications

Research tool:

VSP-G1 nanoparticle generator

Dr. Koolen, could you share some insights into the specific research topic you and your team are currently exploring?

We are developing electrocatalysts that can convert CO2 to high-valued products, i.e. acetaldehyde, a base chemical used in the production of drugs, fragrances, and dyes with a market value of over 1.4B USD. The current process not only uses a petrochemical-resourced feedstock, but it also produces a lot of acid waste, so it is not very clean. Our process runs on just water, CO2, and electricity. Quite green.

Could you describe any challenges or bottlenecks you may have encountered during your research using conventional methods that the VSPARTICLE nanoparticle generator helped you overcome?

I have had to deal first hand with various painstakingly slow and often inconsistently reproducible wet-chemistry recipes to obtain my desired materials. This would take months.

I personally like this anecdote. I had this collaboration with the Paul Scherrer Institute in Viligen (paper still to come out), for which I needed to produce a batch of Cu nanoparticles. We were on a tight schedule. Without timely delivery, the project would have been delayed by months if not postponed indefinitely.

After having spent months on building up a working synthesis protocol, come due date, the synthesis stopped working. I had to spend literally day and night, two weeks straight to come up with an alternative in time.

After the whole ordeal, it turned out that the reagent distributor had changed suppliers and the quality of the precursor we had been using all of a sudden changed. In critical moments like that, consistent reproducibility is key.

VSPARTICLE’s tool offers just that. Once the instrument is calibrated, it works every time.

How has the VSPARTICLE's tool impacted your research and development projects?

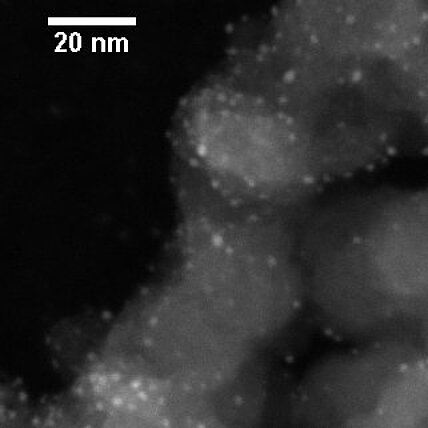

Our desired material has been produced using the wet-chemistry route in the past. Unfortunately, since this material is so extremely unstable, it has always required organic molecules (ligands) to keep it from aggregating. This changes its properties so dramatically that it cannot function properly. VSPARTICLE’s tool has enabled us to produce exactly the right type of material, without the use of any additives and or stabilizers. And this had major implications.

Could you provide an example of improvements or breakthroughs achieved through the application of VSP devices in your work?

The bimetallic cluster electrocatalysts we produce with the nanoparticle generator have resulted in an extremely high selectivity towards acetaldehyde (>90%). This is so significant that we have received interest from industry. And why we have patented the technology.

Any final comments on how VSPARTICLE's technology can drive innovation?

The beauty of the VSP-G1 is that if another laboratory uses our recipe, they can reproduce our synthesis practically instantly. This means that a network of laboratories can be built up with completely different areas of expertise that can all work together. Instead of trying to collect researchers with a vast capacity of skills in one location, one can connect them internationally through the device. This could speed really up finding that breakthrough material. And this is exactly the route we are taking. Collaboratively de-risk our tech to make it industry-ready.

Publication

Discover the scalable synthesis of highly efficient Cu-cluster catalysts with remarkable selectivity and energy efficiency for converting CO₂ into acetaldehyde.

VSP-G1 nanoparticle generator

The VSP-G1 Nanoparticle Generator can either be used as a standalone nano aerosol source or combined with different deposition modules to prepare advanced nanomaterials.

Contact us to learn more about the product and its applications.