Client:

Prof Dr. Vilko Mandić, Associate professor and lead researcher

University of Zagreb, Faculty of Chemical Engineering and Technology

Research field:

Self-assembled nanostructures and nanoparticles for energy applications

Research tool

VSP-G1 nanoparticle generator

Prof. Mandic, could you share some insights into the specific research topic you are currently exploring?

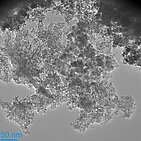

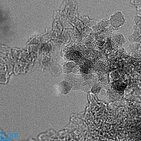

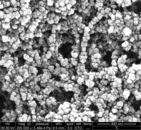

My team is currently exploring metal oxide nanoparticle thin films and how the inherent nature of this method, producing defective metal oxides with metastable energy states, influences photocatalytic and charge carrier transport properties in real device applications.

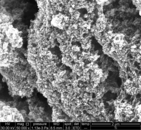

We also create double and triple-layer thin films for which we have a setup of two VSP-G1 devices connected with tubing so the deposition can happen from one nozzle as a mix of materials or via two nozzles so the deposited film can be bilayered. In the case of a split nozzle for one of the two materials, we can theoretically produce a triple A-B-A configuration layer.

Can you describe any challenges or bottlenecks you may have encountered during your research that VSP Nanoparticle Generator helped you overcome?

The area of deposition was an issue for us in terms of technical difficulties. Regarding other issues we’ve had, by far, the hardest one was a structural analysis of the materials, as some of them were poorly crystalline but still had some sort of organization. Even for the crystalline films, sample size and the complexity of the atomic structure made it a real challenge.

In what ways has the VSP-G1 nanoparticle generator contributed to the success of your work in comparison to other methods or devices?

The VSP nanoparticle generator provided a green, solvent-free route to synthesize some high-value materials, like black TiO2 and room-temperature TiN nanoparticles.

Other than product savings, the major saving is the conceptual one, as we avoided the acquisition of an ALD system. The spark plasma ablation deposition (SPAD) method is an ambient deposition method so it is inherently much cheaper than other competing depositions.

In continuation of the previously stated ambient deposition capability, it is its versatility in material and composite synthesis, as well as very small primary particles, which can play to some pretty interesting quantum confinement effects.

Have you experienced any notable improvements in the reproducibility and consistency of results since incorporating the VSP nanoparticle generator into your experiments?

The experiments are quite reproducible, especially in Ar; however, with oxygen introduction into the system, the plasma becomes a bit unstable, so the results don’t always appear to be the same in terms of mass production rate.

Prof. Mandic, you are planning to purchase a VSP-P1 nanoprinter this year. Could you elaborate on how this research tool will facilitate your research?

The P-1 would completely round up the story on photocatalysis and photovoltaic devices. We could print nanolayers of interesting materials and test them in real devices much faster. So the P-1 would enable the scale-up that would facilitate in depth and in-situ, in-operando characterisations.

VSP-G1 nanoparticle generator

The compact size of the VSP-G1 nanoparticle generator ensures that VSPARTICLE’s technology is easily accommodated in every research laboratory with a design able to fit most lab-tables and fume hoods.

Contact us to learn more about the product and its applications.