Client:

CNR-IMM Institute for Microelectronics and Microsystems

National Research Council of Italy (Lecce) | M2DCLab

Dr. Luca Nunzio Francioso, Research Manager

Luciano Velardi, Researcher

Maria Assunta Signore, Researcher

Research field:

Nanostructured materials for MEMS devices, Piezoelectric energy harvesting, Functionalization of biopolymers, Photocatalytic and antimicrobial metal oxide thin films, Diamond films for aerospace and nuclear physics applications, Biosensors for Organ-On-Chip

Research tool:

VSP-G1 nanoparticle generator

Could you briefly introduce yourself and explain how your educational expertise aligns with your research focus involving the VSP-G1?

Educational expertise of our lab researchers is focused on the deposition of materials by chemical and physical techniques and their characterization. The VSP-G1 facility represents an interesting and innovative tool for the improvement of the research group's background, because it enables the exploration of cutting-edge materials investigation in the field of nanoparticle deposition and nanostructured thin films for high-performance microelectronic devices.

Could you share some insights into the specific research topic you and your team are currently exploring?

Currently, we are involved on:

- fabrication of flexible piezoelectric nanogenerators based on AlN thin films grown on common flexible substrates like Kapton or PET.

- fabrication of flexible array of metal electrodes grown on common flexible substrates like Kapton or PET for electrical stimulation of muscle tissue.

- investigation of functionalized Bacterial Cellulose with piezoelectric and photocatalytic nanoparticles obtained by chemical route.

- SERS nanoparticles integration into Organ-On-Chip for non-invasive biosensing.

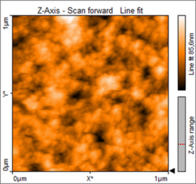

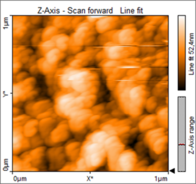

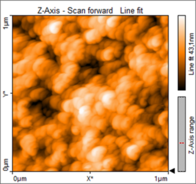

Surface morphology of Au NPs deposited on silicon substrate varying the deposition time: (a) 5 s (b) 180 s (c) 1800 s. By fine-tuning gas flow and deposition time, precise nanoparticles ranging from 20 to 100 nm in diameter were achieved.

Could you describe any challenges or bottlenecks you may have encountered during your research using conventional methods that the VSParticle nanoparticle generator helped you overcome?

The research topics we are exploring, such as the growth of high response piezoelectric materials or photocatalytic and antimicrobial coatings, represent an hard technological challenge. For this purpose, nanostructures are very interesting and the VSParticle nanoparticle generator represents an easy and affordable technique to produce nanostructures of high quality and purity compared to other physicochemical synthesis techniques. These advantages are much more evident for the functionalisation of biocompatible materials or microfluidics for live cells with nanoparticles, making it possible to replace the chemical methods usually employed.

How has the VSParticle's tool impacted your research and development projects?

The possibility to adopt the VSParticle tool as an effective technique to produce nanostructures and nanoparticles of many chemical elements in a simple, inexpensive, and environmentally friendly manner represents an important added value for the future project proposals involving our research team.

Could you provide an example of improvements or breakthroughs achieved through the application of VSP devices in your work?

Depositing high-purity nanoparticles on any solid or porous substrate at room temperature allows the use of countless substrates that could not be used with chemical or physical deposition techniques. Chemicals-free depositions pave the way to large nanomaterials introduction in microphysiological platforms for live tissue modelling and real-time sensors development.

In your opinion, what makes the VSParticle tools valuable for other researchers in your field?

VSParticle generator is a very versatile tool in the field of nanostructured materials growth. It opens new perspectives towards the discover and the investigation of innovative materials by combining elements in an extraordinary way. Moreover, it offers a green approach for nanoparticles deposition that is an extremely important requirement for a sustainable production of nanostructured materials.

VSP-G1 nanoparticle generator

The VSP-G1 Nanoparticle Generator can either be used as a standalone nano aerosol source or combined with different deposition modules to prepare advanced nanomaterials.

Contact us to learn more about the product and its applications.