Thin film coated substrates

for electrocatalysis and gas sensing applications

Ready-to-test coated substrates ideal for rapid prototyping and proof-of-concept studies.

Optimize your research with highly customizable nanoporous thin film samples

We are expanding our offer beyond nanoprinting equipment to include highly customizable nanoporous thin film samples. Produced using our dry spark ablation technology (VSP-P1), the coated samples offer access to our advanced nanoprinting capabilities without the commitment of purchasing the tools.

The ready-to-test coated substrates are ideal for rapid prototyping and proof-of-concept studies, facilitating a practical way to assess performance in your research workflow. Explore the customization options available to meet the practical needs of diverse application environments, including hydrogen production, electrocatalysis, and gas sensing.

Binder free

The dry manufacturing process generates ultra-pure coatings free of chemical contamination.

Low loadings

The reduced loading of coating materials supports both laboratory testing and scalable production.

High porosity

The large surface area increases the number of active sites for electrocatalysis or sensing.

Uniform thickness

The thickness uniformity of the coated layer facilitates efficient and controlled processes.

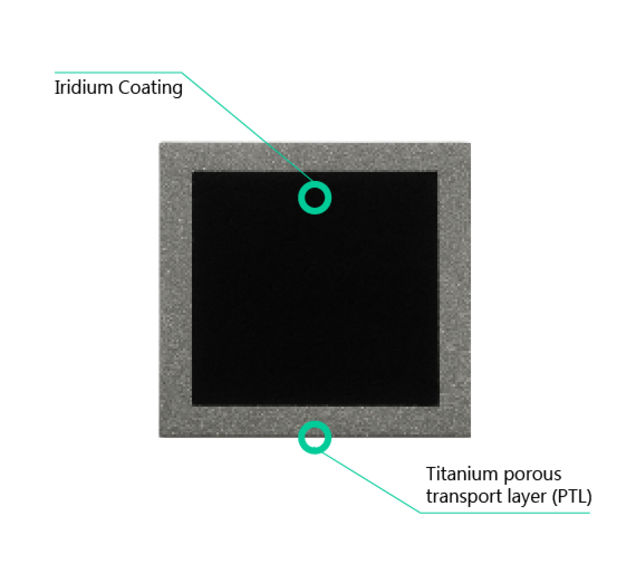

Iridium-coated titanium porous transport layers (PTLs)

Our iridium-coated PTLs are designed for durability in harsh operating conditions. With applications in water electrolysis, N2RR, and CO2RR, the coated PTLs are compatible with both experimental setups and industrial high-current-density environments.

| Substrate | Material | Method | Stability |

|---|---|---|---|

| platinized Ti-PTL | iridium | spark ablation | ambient to 80 °C |

- Customizable loading down to 0.1 mg/cm2

- Flexibility in substrate type and dimensions (up to 15 x 15 cm)

- Large electrochemically active surface area

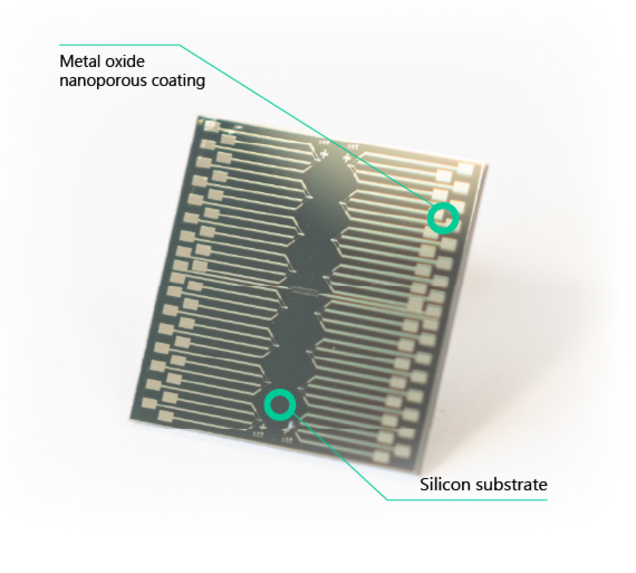

Thin film coated substrates for electrocatalysis

The electrocatalyst coatings are highly customizable for application in water electrolysis (PEM, AEM, AEL, SOE), fuel cells, CO2RR, N2RR, supercapacitors, ion and redox flow batteries, and other fields.

| Method | Loading | Thickness | Dimensions |

|---|---|---|---|

| spark ablation | custom (down to 0.1 mg/cm2) | custom (0.1 – 10 μm) | custom (up to 15 x 15 cm) |

- Compatible with a wide variety of elements (Pt, Ni, Fe, Cu, and other)

- Ratio-controlled material mixing and alloying

- Coated directly onto the substrate of choice (Nafion, Si, Ti PTL, and other)

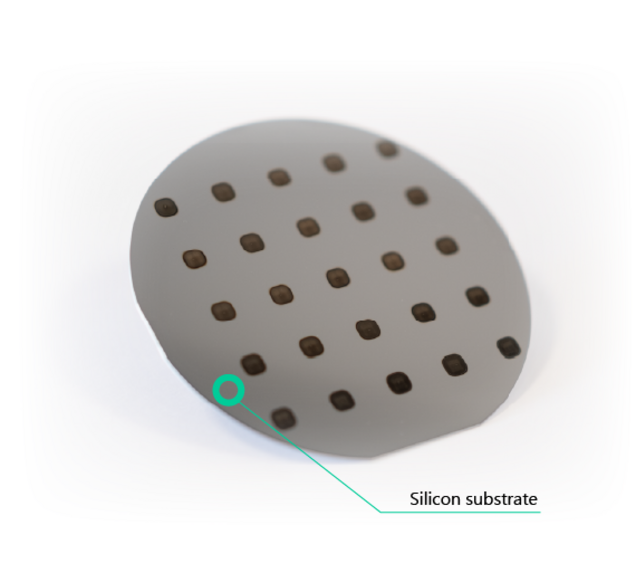

Wafers with nanoporous coatings for gas sensing

Custom sensing materials are deposited directly onto your substrate of choice using VSParticle's dry, mask-less technology. The coatings offer reliable sensing performance to support material optimization processes.

| Substrate | Method | Thickness | Dimensions |

|---|---|---|---|

| custom (wafers, MEMS devices, and other) | spark ablation | custom (down to 100 nm) | custom (up to 6”) |

- Ratio-controlled mixing of metal oxides (ZnO, SnO2, NiO, and other)

- High surface area for an improved figure of merit (FOM)

- Mask-less and dry fabrication of multiarrays