Nanoparticle synthesis in the gas phase

The VSP-G1 Nanoparticle Generator uses spark ablation to produce nanoparticles with primary particle sizes between 1–20 nm. These nanoparticles are produced exclusively in the gas-phase and without the use of any chemical precursors or stabilizing ligands. The spark ablation technology is a scalable, physical-based process which was first reported in 1988 by our co-founder Prof. Andreas Schmidt-Ott. Since its first publication, this innovative and facile nanoparticle generation technology is gaining increasing research interest each year within the field of nanotechnology.

Theoretical background of spark ablation

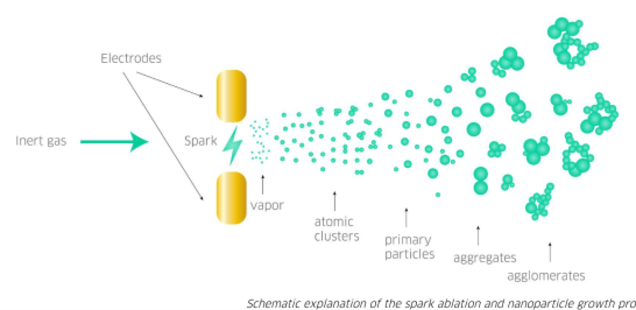

Spark ablation is unique in its simplicity. The only requirements to prepare a continuous aerosol of nanoparticles are electricity, an inert carrier gas and a pair of (semi)conductive electrodes. The electrodes of the desired material are connected to an electrical circuit. A high-purity inert gas is supplied in between the electrode gap and then a high voltage (kV) is applied across the two electrodes. Once the gas breakdown voltage is reached, a spark is generated between the two electrodes and the temperature rises locally (20,000 K), ablating material from the electrode surface. This results in the production of an aerosol of nanoparticles composed of the elements that are present in the bulk electrodes.

Due to the constant flow of the carrier gas, the output of the spark ablation process is a highly concentrated aerosol of nanoparticles (108 – 1011 cm-3) at ambient temperatures (<50 °C). Since this nanoparticle generation process does not require any wet chemical synthesis steps, clean and stable nanoparticles that are free from contaminants (e.g. organic surfactants, solvents, etc.) can be prepared. The generated nanoparticles can either be used as a direct input for a subsequent process step (e.g. detector calibration, core-shell nanoparticle production) or be deposited on various substrates using VSPARTICLE’s deposition accessories to prepare more specialized samples.

Process control parameters

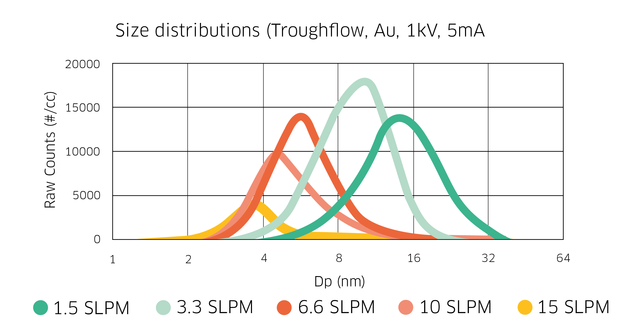

The VSP-G1 Nanoparticle Generator enables you to readily tune the average particle size of a nanoscale material, with particle sizes achievable between 1–20 nm. By adjusting the flow rate of the carrier gas (1–25 L/min for Ar), the voltage (up to 1.3 kV) and/or the current (up to 10.4 mA), the user is able to vary the average particle size. If you are interested in depositing their nanoparticles on substrates using one of the many VSPARTICLE deposition strategies, the surface coverage of a substrate is controlled by varying the power output and deposition time. All the parameters can easily be controlled with the VSP-C1 controller and the integrated software that comes with every VSP-G1.

The most significant parameter to tune the particle size distribution is the flow rate. Higher flow rates ensure that the ablated clusters have little time to agglomerate thereby yielding the smallest nanoparticles. Similarly, lower flow rates will increase the residence time of the ablated material inside the reactor, giving the clusters/particles more time to agglomerate into larger particles. Nevertheless, even at low flows the size distribution of the particles remains narrow. In addition, by adjusting the total power output (i.e. voltage/current) the material ablation rate is varied, with higher voltages/currents resulting in higher ablation rates and therefore generally larger particles.

Material versatility: endless possibilities for new material combinations

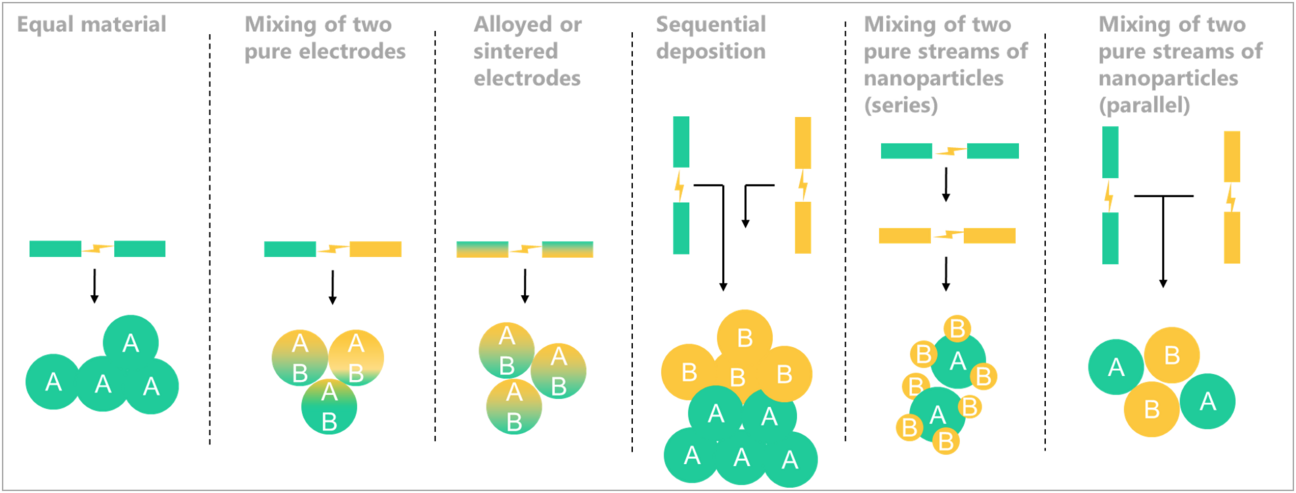

The VSP-G1 is compatible with any conductive or semiconductive material that can be processed into electrodes. That means that all the highlighted green elements of the periodic table are compatible* with the VSP-G1. This gives researchers the freedom to prepare, explore and create a wide range of nanomaterials. The boundaries of exploration are broadened even further by combining electrodes of two different elements/alloys in a single VSP-G1, or by using two VSP-G1 Nanoparticle Generators with different electrode materials in sequence or in parallel. This material versatility allows the production of bimetallic nanoparticles and diverse combinations of nanoalloys even from materials that are immiscible in their bulk form.

Ultimate control of your nanoparticle production: The elemental composition of the generated nanoparticles is primarily determined by the composition of the electrodes. Combined with the lack of additional organic solvents and/or surfactants during synthesis, this allows the ultimate control of your nanoparticle composition. Preparation of oxides is also possible, simply by adding a small amount of oxygen in the gas flow.

In case multiple VSP-G1’s are used or one VSP-G1 with electrodes of two different materials, different elemental combinations of the produced nanoparticles are achieved through different power and flow settings. If you want to discuss further the feasibility of a specific material combination, please contact us.