Understanding the electronic nose: principles, progress, and future directions

Imagine a future in which your smartphone can detect early signs of disease by analyzing biomarker molecules in your breath – or in which your fridge comes with a device that informs you whether your food is about to spoil. With the development of the electronic nose, futuristic scenarios like these are becoming increasingly feasible.

Electronic noses, also referred to as e-noses, are sensor-based systems engineered to replicate the human olfactory system [1]. By combining advanced nanomaterial design with data-driven signal processing, the systems can detect and distinguish complex gas mixtures with remarkable accuracy. With this, electronic noses establish an artificial sense of smell, unlocking new possibilities across environmental, medical, and industrial applications.

This blog post delves into the working principle of the electronic nose and its parallels with the human olfactory system. It highlights its exciting potential across diverse application fields and then explores a critical question: why hasn’t this technology yet transformed our daily lives?

Replicating the human sense of smell

At the core of e-nose technology is a fascinating attempt to replicate how our own sense of smell works. Figure 1 illustrates how e-nose technology bears interesting analogies to the biological olfactory system [2]. Much like the human nose uses millions of olfactory receptors to detect odors, the e-nose relies on an array of highly sensitive sensors that interact with gases in the air. In the human body, the signals picked up by the olfactory receptors are transmitted to the olfactory bulbs, which process the odor into a stimulus for recognition in the brain. In the e-nose counterpart, the interaction of the different sensors with the gaseous mixture creates complex signal patterns, which travel through a circuit where they are amplified and digitized. The signal is analyzed by powerful software that acts as the system's “brain” and uses algorithms to distinguish specific gases from a gaseous mixture based on their individual digital fingerprints.

![Figure 1: Schematic illustration of (a) the biological olfactory system and (b) e-nose technology. Adapted from [2]. E-Nose_Blog_graphics__Recovered_-03](/fileadmin/user_upload/E-Nose_Blog_graphics__Recovered_-03.png)

How can e-noses distinguish gases in a complex mixture?

E-noses rely on a multiarray of partially selective sensors, each of which responds differently to various gases [3]. Rather than using a single sensor to detect a specific compound, e-noses detect patterns of response across the entire sensor array. Because each sensor has a unique response to different gases, the combined output from all sensing units can be used to extract more precise information. Using statistical or machine learning algorithms, the patterns are compared to the digital fingerprints of individual compounds. This enables gas detection with remarkable selectivity, allowing the e-nose to distinguish different gases even in complex mixtures.

Get access to our application note that describes the dry, mask-less fabrication of sensor multiarrays with VSParticle's nanoprinting technology.

Application fields of e-nose technology

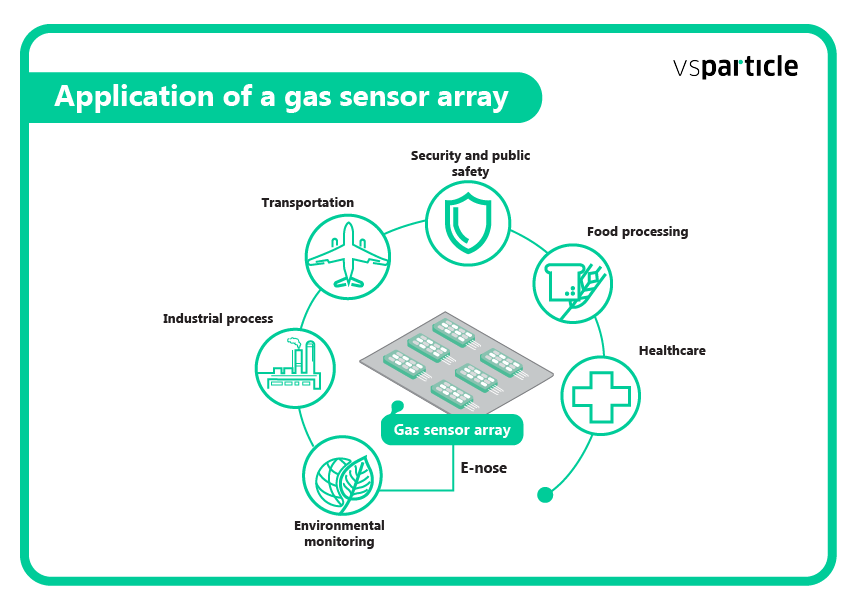

With the ability to discriminate individual target gases from complex gaseous mixtures, e-noses are unlocking new possibilities across a wide variety of application fields (Figure 2) [4]. In healthcare, they are being developed for non-invasive disease diagnostics by detecting volatile biomarkers in breath. In the food and beverage industry, e-noses could assist in quality control, freshness monitoring, and even flavour profiling. Environmental monitoring is another key area, where e-noses could help track air pollution, detect hazardous gases, and support early warning systems in industrial settings. Additionally, e-nose devices are promising for applications in agriculture for soil analysis, crop monitoring, and early detection of plant diseases.

Has research on e-noses lost momentum?

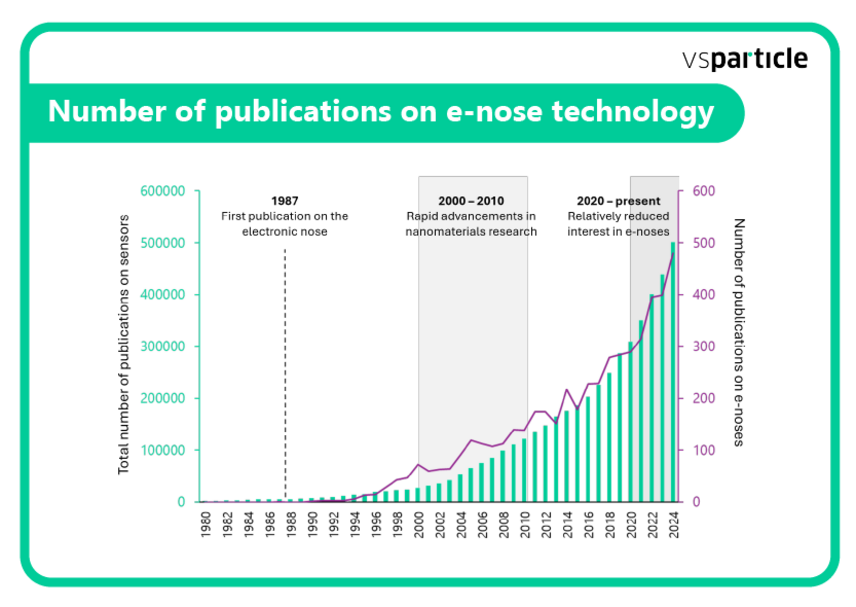

While the initial excitement around electronic noses (e-noses) were huge, their widespread use in everyday technology still hasn't materialized, even after a few decades of research. Although the number of publications on e-noses has been steadily rising, their commercial availability and practical applications remain limited.

Looking at the publication trends over time, we see a clear picture. As shown in Figure 3, the purple line represents a steady increase in e-nose research since the first paper in 1987, showing that interest in the field hasn't waned. In fact, from 2000 to 2010, when nanomaterials were gaining traction, e-nose research was growing faster than the broader sensor field – the boom in nanomaterials research appears to have given e-noses a significant push forward in this time period. However, in more recent years, e-nose research has made up a smaller slice of the overall sensor research pie, signalling that momentum in the field may have slowed.

Future directions

What’s next for e-noses? To unlock the full potential of e-noses, the field may need a new leap forward: one grounded in recent advances in nanomaterials science. At VSParticle, we believe that our innovative nanoprinting technology could provide the technological advancement that is necessary to give a new stimulus to the field. Our approach enables the fabrication of highly controlled nanoporous sensing layers, which, when combined with the rapid progress in artificial intelligence, could facilitate the transition of e-noses from promising prototypes to mainstream technologies.

In our next blog post, we will explore in more detail how VSParticle's nanoprinting technology addresses key challenges in chemiresistive sensor development for electronic noses.

References

[1] S.Y. Park, Y. Kim, T. Kim, T.H. Eom, S.Y. Kim, and H.W. Jang. “Chemoresistive materials for electronic nose: Progress, perspectives, and challenges.” InfoMat 1.3 (2019). doi.org/10.1002/inf2.12029

[2] P.E.S. Munekata, S. Finardi, C. Krebs de Souza, C. Meinert, M. Pateiro, T.G. Hoffmann, R. Domínguez, S.L. Bertoli, M. Kumar and J.M. Lorenzo. “Applications of Electronic Nose, Electronic Eye and Electronic Tongue in Quality, Safety and Shelf Life of Meat and Meat Products: A Review.” Sensors 23(2) (2023): 672. doi.org/10.3390/s23020672

[3] S. Mor, B. Gunay, M. Zanotti, M. Galvani, S. Pagliara, and L. Sangaletti. “Current Opportunities and Trends in the Gas Sensor Market: A Focus on e-Noses and Their Applications in the Food Industry.” Chemosensors 13.5 (2025): 181. doi.org/10.3390/chemosensors13050181

[4] A.D. Wilson and M. Baietto. “Applications and advances in electronic-nose technologies.” Sensors 9(7) (2009): 5099-5148. https://doi.org/10.3390/s90705099

[5] J.W. Gardner and P.N. Bartlett. “A brief history of electronic noses.” Sensors and Actuators B, 18-19 (1994): 211-220. doi.org/10.1016/0925-4005(94)87085-3

[6] T. Aishima. “Aroma discrimination by pattern recognition analysis of responses from semiconductor gas sensor arrays.” J. Agri Food Chem., 39 (1991): 752-756. doi.org/10.1021/jf00004a027

[7] T. Nakamoto, A. Fukada, and T. Moriizumi. “Perfume- and flavour identification by odor sensing system using quartz resonator sensor array and neural-network pattern recognition.” Sensors and Actuators A, 10 (1993): 85-90. doi.org/10.1016/0925-4005(93)80030-F