Offering a new technology to unlock new material properties and solve the world’s biggest challenges

Welcome and thank you for choosing VSPARTICLE!

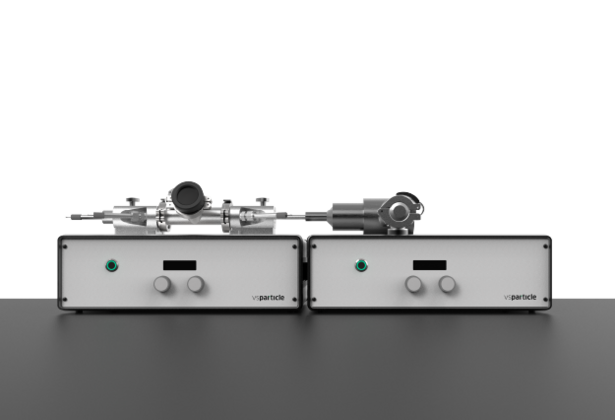

This portal will explain you everything there is to know about the VSP-G1; product documentation, basic experimental design and getting started content.

At VSPARTICLE, we believe that generation of nanoparticles should be neither complex nor time-consuming. This is why we developed the VSP-G1 Nanoparticle Generator. Our technology reduces the preparation time of advanced nanoparticle samples, ready for analysis to a matter of hours, enabling researchers to accelerate the process of developing novel materials and immediately investigate their unique properties.. Our products empower material pioneers!

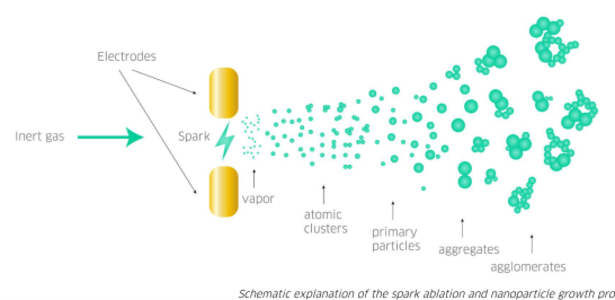

Nanoparticle synthesis in the gas phase

The VSP-G1 Nanoparticle Generator uses spark ablation to produce nanoparticles with primary particle sizes between 1–20 nm. These nanoparticles are produced exclusively in the gas-phase and without the use of any chemical precursors or stabilizing ligands. The spark ablation technology is a scalable, physical-based process which was first reported in 1988 by our co-founder Andreas Schmidt-Ott. Since its first publication, this innovative and facile nanoparticle generation technology is gaining increasing research interest each year within the field of nanotechnology.

Spark ablation technology is a physics based process, generating pure particles in a very controlled setting, without the use of chemicals. Our co-founder Andreas Schmidt-Ott invented the technology in 1988 and was then developed into an easy to use device.The spark ablation process used inside the VSP-G1 Nanoparticle Generator (VSP-G1) is a purely physical process that only requires electricity, a carrier gas and electrode material to produce clean nanoparticles. No additional chemicals are required for the production or to stabilize the particles in the aerosol.

Are you interested learning more about the origins and current state-of-the-art of spark ablation, please visit our Publications page!

For details please visit our output estimator page.

Reproducible samples with size selected nanoparticles in <60 minutes

The VSP-S1 is a table-top, user-friendly nanoparticle size-selector that can be easily connected to the VSP-G1. Together, they enable the automated production of size-selected inorganic nanoparticle (1-10 nm) samples, with minimal effort. Compatible with any (semi-) conductive material (alloy or non-alloy), you simply select the size and wait for your sample to be ready. Typical sample preparation time is 30-60 minutes.For more details visit VSP-S1 Size Selector page.

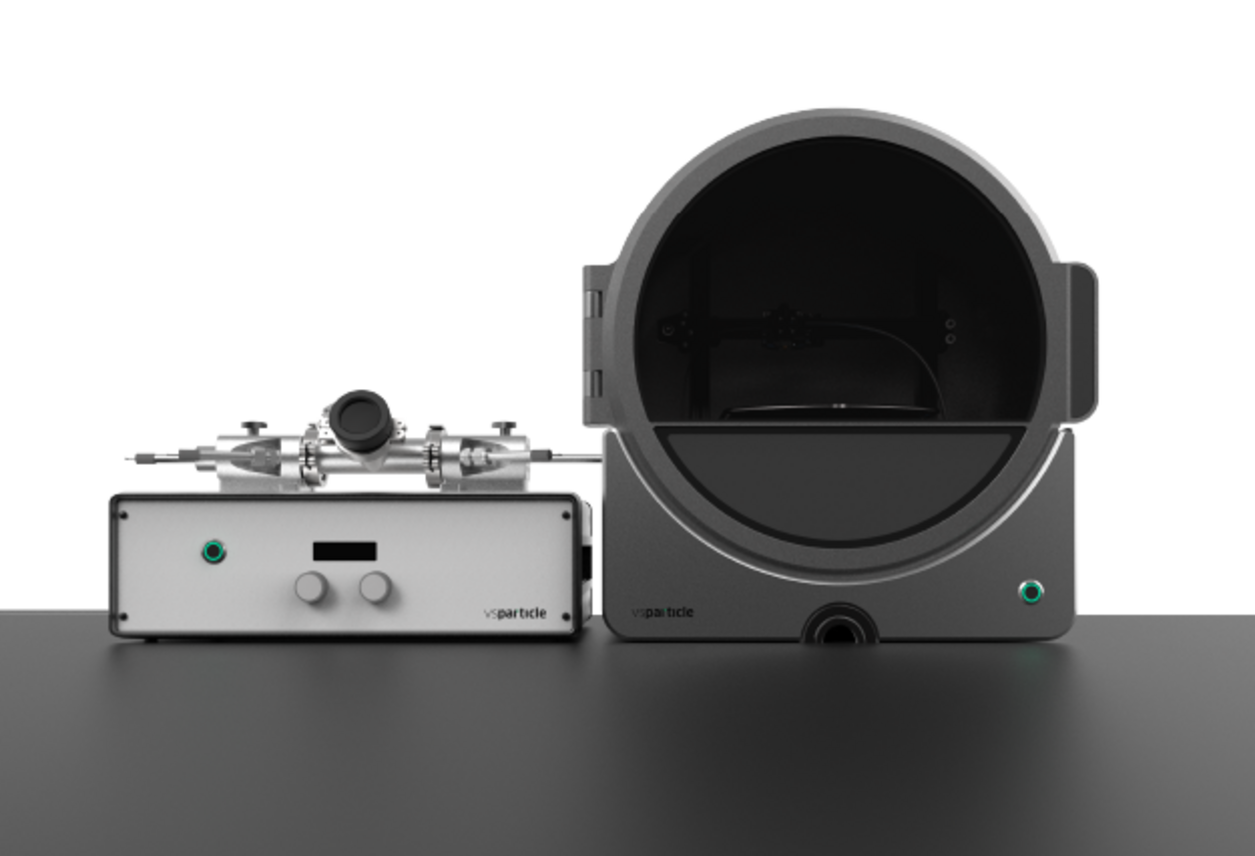

Local deposition of nanoporous thin-films

When connected to the output of the VSP-G1, the VSP-P1 enables you to print inorganic nanostructured materials with novel properties. The material is built-up of sub 20nm pure particles, and can be printed in patterns locally on any type of substrate.For details visit VSP-P1 Nanostructured Material Printer page.

Please find more information about our Blogs and News here .

A community that wants to create a new way of collaboration, resources and infrastructure to support scientists and researchers in the effort to discover, manufacture and develop new materials.

Our aim is to lead a culture shift in material science research to encourage and facilitate an integrated team approach. And we can only do this with your help. For more details visit Material Pioneers website here.