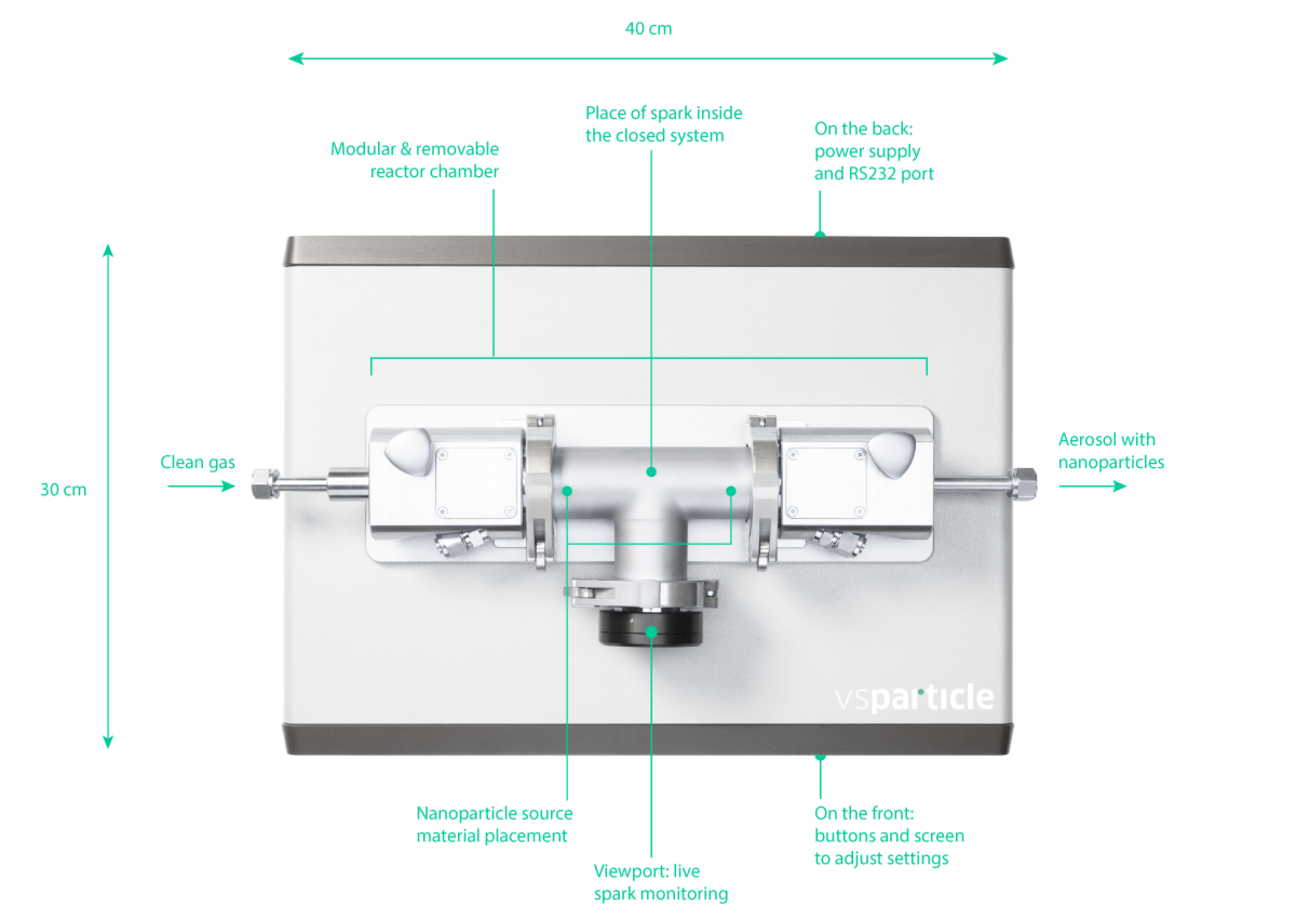

VSP-G1 Nanoparticle Generator

A table-top, user-friendly nanoparticle generator that is the basis of all VSPARTICLE products.

The standard in nanoparticle generation

The VSP-G1 Nanoparticle Generator is a tabletop solution for generating pure metal, metal oxide, or alloy nanoparticles in the size range of 1 – 20 nm. The nanoparticle production takes place entirely in the gas-phase and thus there is no need to use surfactants or precursors. The source material for the nanoparticle production are two rods (electrodes) made from the desired material. Simply load the electrodes and set the process parameters to start generating nanoparticles at the push of a button. All VSPARTICLE products are designed with a modular approach, hence the VSP-G1 Nanoparticle Generator can either be used as a standalone nano aerosol source or can be combined with different deposition modules for the preparation of advanced nanomaterials.

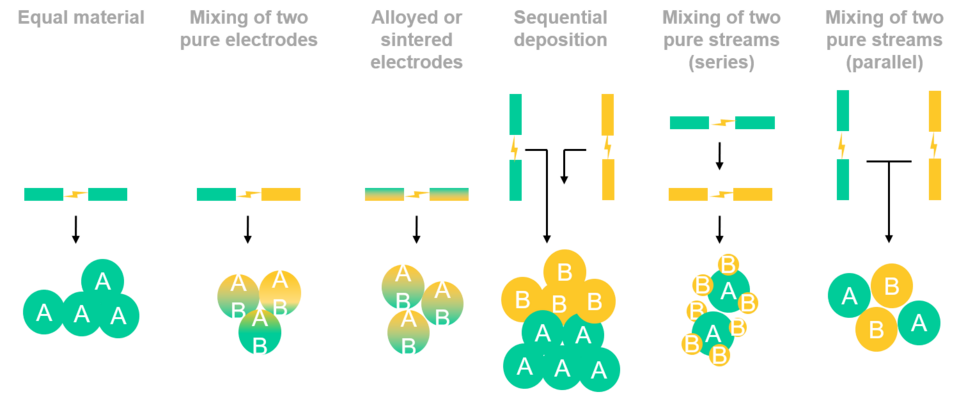

Mix and Match Materials

Material versatility is key for reducing research iteration times and unlocking materials with unique properties. VSPARTICLE's technology enables you to change the material easy and fast by using the plug-and-play electrode system. Different configurations enable the creation of particles such as bi-metals, nano-alloys or materials that are immiscible in bulk state. All (semi)conductive materials that can be processed into electrodes are compatible with the VSP-G1 Nanoparticle Generator.

Preparation of advanced nanomaterials

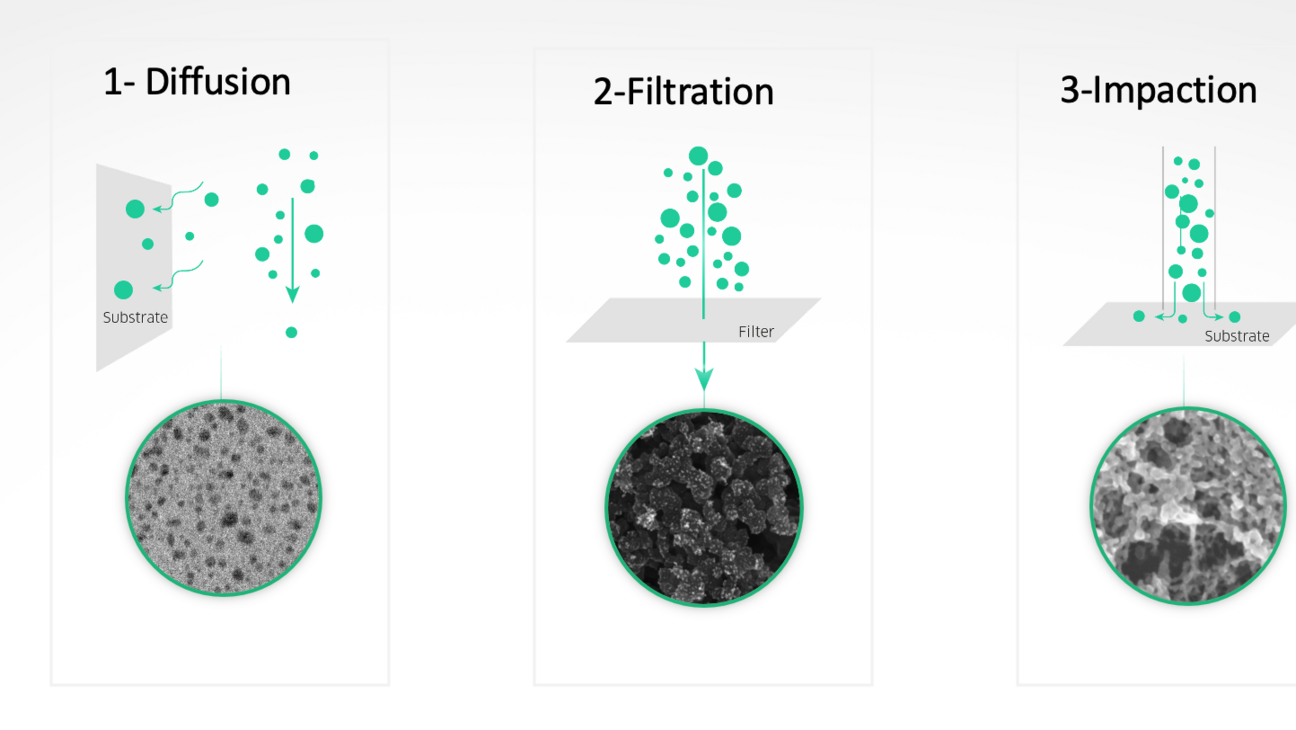

Due to its modular design, the VSP-G1 Nanoparticle Generator can easily be combined with a deposition unit for the preparation of advanced nanomaterials. There are different deposition modules available based on diffusion, filtration or impaction techniques. There is also the option to narrow the size distribution of the nanoparticles even further with the use of the S1 Size Selector. Talk to our specialists by filling the form below, to determine which approach is most suitable for your application and needs.

Client Stories

Download Brochure

The compact size of the VSP-G1 nanoparticle generator ensures that VSPARTICLE’s technology is easily accommodated in every research laboratory with a design able to fit most lab-tables and fume hoods.

Download the brochure to learn more about the product and its applications.