New era for material discovery

We are at a pivotal moment in history, where advancements in artificial intelligence (AI), robotics, and automation are revolutionizing material discovery at an unprecedented pace. This transformation accelerates the identification and optimization of novel materials, including one of the most promising material categories in our fight against climate change – electrocatalysts.

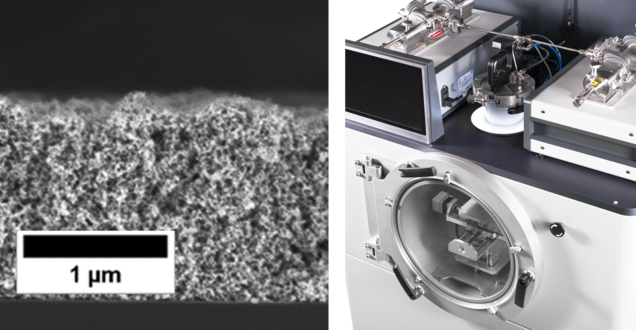

At VSParticle, we developed a unique single-step method for fast, easy, and scalable synthesis of nanoporous layers, boosting the performance of catalyst materials.

Meta and VSParticle launch first and largest catalyst database to accelerate clean energy transition

In a landmark collaboration with Fundamental AI Research (FAIR) at Meta, VSParticle's state-of-the-art nanoporous layers printing technology was used to rapidly synthesize a large dataset of various catalyst materials from diverse elemental compositions to discover materials to combat climate change.

The Open Catalyst Experiments 2024 project aims to accelerate the path of discovery to manufacturing of catalyst materials by producing, printing and testing datasets of hundreds of unique and diverse materials in the lab that AI had predicted as the best candidates for CO2 Reduction Reactions (CO2RR).

Get access to the detailed analysis of alloy catalysts datasets synthesized with VSParticle technology for Meta's Open Catalyst Experiments 2024

The race for better catalysts: why nanoporous layers hold the key

The urgent need for high-performing catalysts has never been more critical to large-scale energy storage and converting CO₂ into valuable molecules. At the heart of catalytic performance lies the quality and structure of nanoporous layers, which provide the larger specific surface areas and more active sites essential for enhanced catalytic reactions.

However, there is a huge unmet need for high-performance nanoporous layers since conventional wet synthesis methods fall short. They lack the precision and scalability necessary to produce nanoporous materials when rapid innovation is imperative. This is where VSParticle steps in to bridge the gap.

Synthesizing the most advanced nanoporous materials ever made

VSParticle offers disruptive technology to produce a new class of advanced nanoporous layers synthesized with the smallest and purest nanoparticlesever produced. These intricate nanostructured materials hold the key to faster innovation in the energy sector, allowing researchers and industries alike to meet the world’s most pressing challenges head-on.

VSParticle's nano printing technology leverages proprietary Spark Ablation technology to generate pure nanoparticles of <5nm and create nanoporous thin films in a single-step, automated, and fast process.

This innovative approach significantly enhances the potential for combinatorial material discovery by enabling researchers to explore countless combinations of approximately 70 elements from the periodic table, resulting in a vast array of novel materials with unique properties.

Fueling AI with large experimental datasets

In the race to find optimal materials, speed is critical. Self-driving material discovery labs rely on one critical component—comprehensive and accurate experimental datasets to train AI models that can predict the best material combinations. This is a process that traditional wet chemistry methods simply can’t match in speed or scale.

VSParticle offers the best-in-class synthesis platform for combinatorial material discovery. Our flagship VSP-P1 Nanoprinter, coupled with one or more nanoparticle generators, offers unparalleled speed and precision in producing high-throughput samples with a wide variety of desired material combinations and alloyed catalysts for training predictive AI models.

Discover what’s possible with our nano printing technology

Bridging the gap between experimental research and real-world applications

Once the ideal catalyst materials are identified in the lab, the next step is the scaled production to match the growing industrial demand of the electrolyzer market. However, the manufacturing process requires advanced technologies that can achieve high-volume production while remaining cost-effective and time-efficient.

To bridge this gap, VSParticle is developing the next generation of VSP-G100 nanoparticle generators, capable of producing nanoparticles at 100 times the mass output. This innovation will lay the grounds for our High Volume Production Tool (HVPT), which will integrate multiple VSP-G100 generators within a single printer for industrial-scale production of nanoporous layers for the electrolyzer stack, offering the most cost-effective, simple, and automated solution for this essential component of green hydrogen production.