Revolutionizing PEM Electrolysers | Reducing Iridium loadings by 10 times using VSPARTICLE's nanoprinting technology

VSParticle aims at reducing costs and mitigating risks associated with the production process, with the ultimate objective to make green hydrogen more accessible and viable.

In collaboration with CLEANHYPRO, VSParticle is enhancing its pilot production line to manufacture catalyst layers composed of iridium nanoparticles, a critical component in the electrolyser stack. CLEANHYPRO is leading an initiative to create a single entry point for industrial partners, particularly small and medium-sized enterprises (SMEs), to scale up the production of electrolysis materials and components essential for green hydrogen production

Concurrently, VSParticle is collaborating with consortium partners to assess the performance of these catalyst layers in an industrial setting, demonstrating their effectiveness and potential for widespread use.

Iridium a critical resource for green hydrogen production

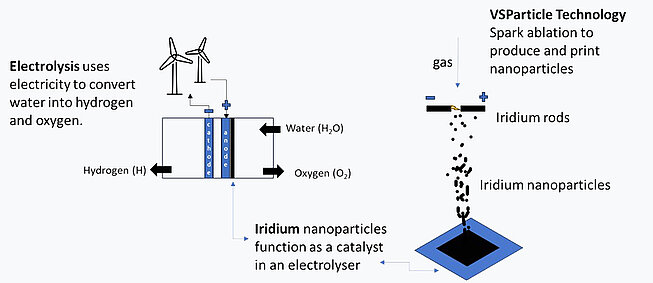

Proton Exchange Membrane (PEM) water electrolysis is emerging as a key technology for the transition to green hydrogen. This process uses an electrochemical cell with a catalyst-coated membrane (CCM) to split water into hydrogen and oxygen using electrical energy. The CCM, a crucial component of the electrolyser stack, is coated with iridium (Ir). Iridium efficiently splits water molecules into hydrogen and oxygen without being consumed in the process, enhancing the efficiency of electrolysis.

Iridium remains exceptionally rare, with its mining process posing considerable challenges and costs. Globally, the annual extraction of iridium from mines amounts to only about 7 – 8 metric tons.[1,2] All of iridium is consumed in different applications such as electrical, chemical, medical, etc., with less than 1% being utilized for hydrogen production thus underscoring the metal's scarcity and the challenges involved in its limited availability for anticipated hydrogen growth.

Furthermore, iridium can account for about 20-25% of electrolyser stack costs.[3] Therefore, limited availability of iridium and high costs make it imperative to reduce its usage and recycle as much as possible. In this blogpost we will discuss how VSParticle addresses these challenges.

Iridium constraints for current and future demand for PEM electrolysis

With current technologies, ~300-400 kg of iridium is required for each GW of PEM electrolysis capacity, with total installed capacity of PEM electrolysers of only 0.2 GW in 2022.[4] The current loading of iridium per GW of electrolyser capacity is quite high which is a big bottleneck towards industry’s ambition to grow hydrogen production.

International Energy Agency (IEA) estimates that an installed electrolyser capacity of 170-365 GW can be realized by 2030 if all the green hydrogen projects in the pipeline materialized.[4] With an assumed market share of 30% for PEM electrolysers, it would require 15 mt – 43 mt of cumulative iridium demand by 2030. Given the scarcity and expense of Iridium, optimizing its use is critical for the sustainability and scalability of green hydrogen production.

Economic impact of limited Iridium recycling

The current global end-of-life (EOL) recycling rate of iridium is relatively low, ranging from 20-30%[5]. This limited recycling efficiency is primarily due to the challenges in collecting EOL materials and the low concentration of iridium in many applications, necessitating significant pre-treatment processes. As a result, the market experiences large price fluctuations, with iridium prices exceeding €160,000 per kilogram[6]. Additionally, the applications of iridium are not easily replaceable, further exacerbating the impact of its scarcity and high cost on various industries.

VSParticle Nanoprinter mitigating Iridium usage

VSParticle's catalyst addresses these challenges by enhancing efficiency and reducing material loading, thereby improving performance and cutting costs. VSParticle's state-of-the-art VSP-P1 Nanoprinter technology uses VSP-G1 nanoparticle generator that is based on spark ablation technique to generate extremely small particles (2 nm) from bulk rods using electricity and a carrier gas (Figure 1). These iridium nanoparticles serve as catalysts in the electrolyser, offering high efficiency due to their large surface-to-volume ratio, which reduces the amount of iridium needed in the process. VSP-P1 has already achieved iridium loading of 0.4 mg/cm2[7].

Targets on further reduction in Iridium loading and print time

VSParticle is integrating the next generation of nanoparticle sources in the Nanoprinter to significantly speed up the printing process—a major step towards industrial relevance. The goal is to reduce iridium loading to less than 0.1 mg/cm² while maintaining performance and stability, compared to current loadings in PEM electrolysers of 1 mg/cm², resulting in 10 times less iridium use for hydrogen production.

VSParticle is also optimizing the flow path of nanoparticles within the system to ensure more produced nanoparticles end up on the substrate. Additionally, efforts are underway to collect and recycle all iridium nanoparticles lost in the process, further enhancing the sustainability of the production by reusing 80% of the process gas.

Breakthrough in nanoprinting: Less Iridium loading and reduction in print time

We have successfully integrated the next generation of nanoparticle source, and our first samples have been printed for characterization (Figure 2).

One notable success achieved through this advancement is the reduction in print time to just one minute for a 2.5x2.5 cm² area with a loading of 0.1 mg/cm². This progress represents a significant step towards upscaling the production of nanoparticles to an industrial scale. By upgrading nanoprinting technology, increasing output, reducing losses, and recycling waste, VSParticle aims to minimize costs and risks, thereby accelerating market adoption and scalability.

Unlocking multi-GW scale hydrogen production

The targets for green hydrogen production are ambitious, with the aim to produce substantial quantities of hydrogen per year and significantly increase the adoption of PEM electrolysers.

VSParticle is committed to further reducing the amount of iridium required and continues its mission to enable researchers to discover novel nanomaterials with unique properties that can solve global challenges. By utilizing nanotechnology for material development, VSParticle aspires to further optimize the use of iridium to unlock multi-GW scale hydrogen production while amplifying research efforts to discover better catalyst materials that do not rely on Earth's rarest elements.

A leap forward in Green hydrogen efficiency

VSParticle's advancements in iridium nanoparticle technology under the CLEANHYPRO initiative mark a significant step towards making green hydrogen production more efficient, cost-effective, and sustainable. By reducing iridium usage while maintaining the catalyst efficiency, and improving recycling processes, VSParticle is paving the way for the broader adoption of green hydrogen technologies. The collaboration with consortium partners and continuous innovation will be crucial in overcoming current challenges and achieving the future targets for hydrogen production.

Acknowledgment

Special thanks to Pauline Roels (Product Owner), Coosje Pothoven (Application Engineer), Erdem Irtem (Application Specialist, Electrochemistry), and Nayab Azam (Technical Content Writer) for contributing and sharing their knowledge and expertise in writing this blog post.

References

[1] Statista (2023), Supply of Iridium worldwide from 2021 -2023

[2] 240,000 ounces which is converted to metric tons using a division factor of 32,000.

[3] International Energy Agency (2022), Tracking Electrolysers

[4] National Renewable Energy Laboratory (2024) Updated Manufactured Cost Analysis for Proton Exchange Membrane Water Electrolyzers

[5] International Journal of Hydrogen Energy (2021), Is iridium demand a potential bottleneck in the realization of large-scale PEM water electrolysis?

[6] Umicore (2024) Sales Price

[7] Catalysts (2022), Spark Ablation for the Fabrication of PEM Water Electrolysis Catalyst-Coated Membranes

Comments

No Comments